Ball screw repair service done on-site.

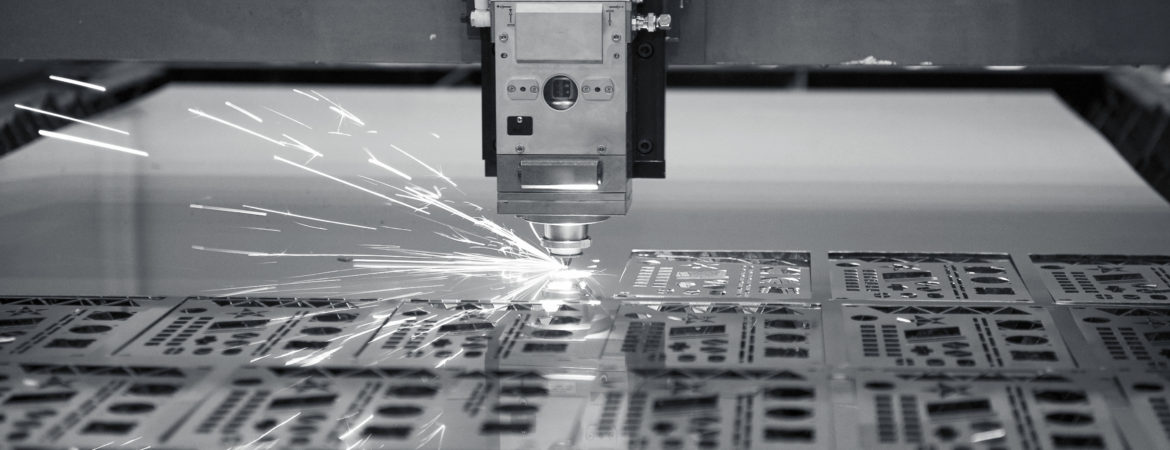

CBR provides ball screw repair for lasers, water jets, routers, and more.

What causes worn, loose, and noisy ball screw assemblies?

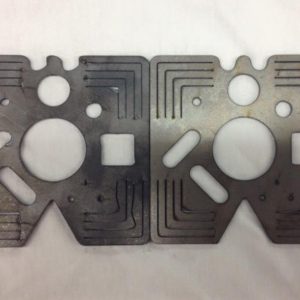

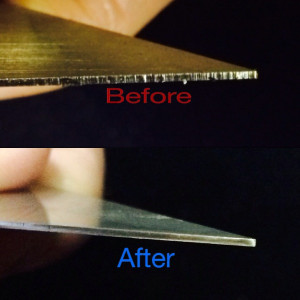

Most CNC metal-working machines tend to loosen up with age and production hours. It is very common to see laser machines with only 4,000 to 6,000 hours on them showing “hole out-of-round” problems, tool chatter, loss of stiffness, interpolation errors and poor finish pass accuracy. These issues are not a machinery quality problem; it is usually caused a ball screw assembly worn from abrasive cutting effluents suspended in the air and blown around by the assist gas. This dust is very fine and tends to coat everything on or near the machine, impacting the integrity of the ball screw assembly.

Over time, this leads to the need for ball screw repair, restoration, or worst-case scenario – replacement. Regular preventive maintenance with CBR can extend the life of your ball screw.

Field service CNC ball screw repair ensures the least downtime and the least lost production.

Even with travel expenses, our prices are lower than most repair depot estimates/invoicing. See our Cost Examples page for a sample comparison and contact us for a custom service quote.

The Best Casino Online Uk | Online casino games: roulette, blackjack and others

Big Dollar 100 Free Spins – Casino minimum wager 10 cents

Play Igt Slots Free Online | Calculate the odds of winning at slots

Casino Card Dealer | How to use online at online casino

Ball screw repair doesn’t have to cost a fortune!

Contact us to learn how we can get you back to cutting quality parts

at a fraction of the cost of replacing or rebuilding your ball screw.

(And YES, we warranty our work!)

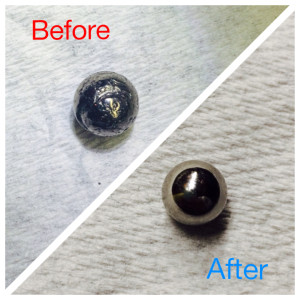

Worn ball bearings can pit, chip, or crumble – causing your ball screw assembly to seize or lock up. CBR service professionals inspect and complete full-set bearing replacements.

Minimize Lost Production Time

90% of ball screw assemblies can be repaired on site, ensuring the least amount of downtime. Some manufacturers have a 6-12 week wait for replacement – time you can’t afford to wait. Our on-site repairs are typically completed in 8-10 hours!

Increase Feed Rates

Has production slowed to compensate for accuracy issues? Our service will maximize your feed rates.

Save Big Bucks!

Call us when your ball screw assemblies get loose or noisy, before they seize up. On-site service avoids assembly replacement and regrinding, keeping your repair costs down.

Prevent Ball Screw Failure

If you have acquired a used piece of machinery or have not had your ball screws regularly inspected, call to schedule an inspection to ensure there are no wear issues.

Ensure Best Performance

Regular inspections and clean/flush service will improve the service life of your CNC equipment.

Questions?

Contact us today!